Overview

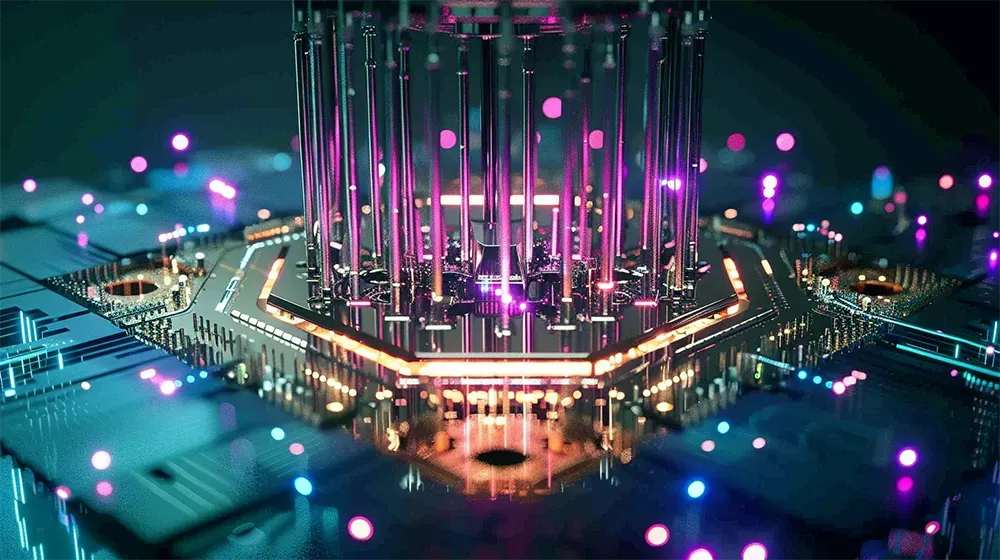

Quantum computing is a wild leap forward for technology, all thanks to the power of qubits. These strange components can be both one and zero at once, which is honestly mind-bending and gives quantum machines a serious edge in processing power.

But there’s a catch—building and keeping these fragile structures running isn’t easy. It pushes researchers to rethink manufacturing and lab environments from the ground up.

The Role of Quantum Cleanrooms

Quantum computers need a whole new level of cleanroom design. Standard cleanrooms, usually ISO 7 or ISO 8, just don’t cut it for quantum gear.

Those older standards let in too many particles, which can mess with the super-sensitive parts inside quantum systems. So, the industry has shifted to stricter standards—think ISO 6 or even better.

These upgraded cleanrooms keep out nearly all particles bigger than 0.5 microns. That’s a pretty important detail when you’re working with nanoscale materials.

Inside these rooms, you’ll find some hardcore air filtration, tight temperature control, and cleaning routines that border on obsessive. Researchers have found that low-temp vacuums and less aggressive cleaning actually help quantum components work better.

It’s not just about being clean—it’s about stability and keeping outside influences at bay. That means less risk from static, dust, or even random electrical noise.

Integration of Advanced Materials

Quantum computers lean heavily on nanotechnology and specialized materials. Most parts are built from nanomaterials that handle heat and electricity way better than anything in regular computers.

These tiny materials let engineers cram in more transistors, keeping up with Moore’s law while still running efficiently under heavy loads. But, as you might guess, they’re pretty delicate.

Even a speck of dust or a stray chemical can ruin them. Quantum cleanrooms fight these problems by dialing in the environment for maximum protection.

For example, special lighting keeps out damaging wavelengths, and tight temperature controls protect superconductors that hate sudden changes.

Semiconductor Challenges in Quantum Manufacturing

Semiconductors are still the core of quantum machines, but fitting them in is a real headache. Building these parts for quantum use means working at the atomic level, with zero room for error.

Techniques like atomic layer deposition (ALD) help lay down perfect, uniform layers—no defects allowed. This kind of precision is key for getting superconducting properties in qubits.

Of course, new methods bring new headaches. Even tiny mistakes in semiconductor fabrication can throw off an entire batch.

That’s why teams spend so much time on R&D, tweaking processes to boost yields and reliability for quantum projects.

The Demands of Innovation

Pushing quantum computing forward takes massive investment—both in gear and in people. Teams have to constantly update their skills and methods for these weird, finicky materials and circuits.

It’s a mashup of chemistry, physics, materials science, and engineering. No one field can tackle it alone, honestly.

The cost is no joke. Upgrading a cleanroom for quantum work is expensive, time-consuming, and sometimes feels like a never-ending project.

Still, the potential payoff? Huge. Quantum information processing could totally shake up cryptography, drug discovery, AI, and who knows what else.

| Key Considerations for Quantum Cleanrooms | Description |

|---|---|

| Air Quality | Stringent filtration to manage sub-0.5 micron particles. |

| Temperature Control | Precise regulation to ensure material stability. |

| Lighting | Warm-spectrum lights to avoid sensitivity issues. |

| Cleaning Methods | Gentle techniques to protect fragile components. |

Preparing for Future Manufacturing

Quantum computing isn’t slowing down, and neither are the demands for better labs and gear. Manufacturers have to focus on top-tier equipment, bleeding-edge materials, and strict environmental controls.

By tackling these challenges, engineers and researchers are opening the door to breakthroughs we can barely imagine right now.

Frequently Asked Questions

What are the key design elements needed for building a quantum cleanroom?

Quantum cleanrooms need ultra-low contamination. Advanced filtration systems remove even the tiniest particles, vibrations, and interference.

Precision air handling and specialized materials keep things pure. It’s a lot more work than a regular lab, honestly.

In what ways do quantum fabrication environments differ from traditional computer labs?

Quantum labs take environmental control to a whole new level. They clamp down on electromagnetic interference and temperature swings way more than traditional facilities ever have to.

What specific conditions are necessary to ensure quantum coherence?

Quantum coherence depends on rock-steady temperatures, almost no vibrations, and strict control of electromagnetic fields. Even tiny wobbles can throw things off and wreck computational accuracy.

How does contamination affect the development of quantum computing systems?

Contamination—dust, stray chemicals, you name it—can ruin quantum components. These problems cause defects or outright failures, so keeping things spotless is absolutely critical.

What progress has been made in designing better environments for quantum computing?

There’s been a lot of progress: better isolation, smarter air filtration, and heavy-duty shielding against noise and electromagnetic nastiness. These upgrades are custom-fit for quantum fabrication’s crazy demands.

What obstacles hinder the scaling of quantum computer production?

Scaling quantum computers? It’s tricky. You need almost flawless environmental control.

Manufacturing has to be incredibly precise, too. There’s not much room for error.

On top of that, specialized materials are tough to get. The high costs really drag out large-scale production.